Making of a Lens

Feb 24 2020

Lenses are made of optical glass or plastic. They focus light rays by refracting or bending them so that they meet or converge at a common point.

A simple lens “sees” well through its center, but its vision around the edges tends to blur. Blurring, color changes, distortion of lines, and color halos around objects are caused by defects in the lens called aberrations

A ca

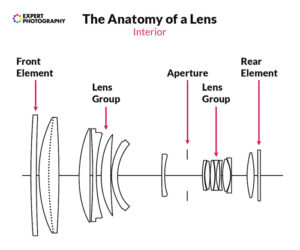

camera lens reduces the effects of aberrations by replacing a simple lens with a group of lenses called lens elements, which are lenses of different shapes and distances of separation. The lens becomes more complex as greater correction of vision is achieved.

The convex lens curves outward; a biconvex lens curves outward on both sides, and a plano-convex lens is flat on one side and outwardly curved on the other. There are also concave lenes, biconcave, and plano-concave lenses.

Optical glass is supplied to lens manufacturers by specialized vendors. Usually, it is provided as a “pressed plate” or sliced glass plate from which the elements are cut. The glass elements are shaped to concave or convex forms by a curve generator machine that is a first-step grinder. To reach the specifications for its shape, a lens goes through a sequence of processes in which it is ground by polishing particles in water. The polishing particles become smaller in each step as the lens is refined. Curve generation and subsequent grinding vary in speed depending on the frailty, softness, and oxidation properties of the optical materials.

- The barrel includes the chassis that supports the various lens elements and the cosmetic exterior. Metal mounts, grooves, and moving portions of the lens are critical to the performance of the lens, and are machined to very specific tolerances. Lens mounts may be made of brass, aluminum, or plastic.

- Most metal barrel components are die-cast and machined. Metal mounts last longer, maintain their dimensions, can be machined more precisely, and can be dismantled to replace elements, if necessary. Plastic mounts are less expensive and of lighter weight.

the he barrel is made of engineering plastic, it is produced by a highly efficient and precise method of injection molding. The interior surfaces of the barrel are also coated to protect them and to prevent internal reflection flare.

Formed lenses are coated to protect the material from oxidation, to prevent reflections, and to meet requirements for “designed spectrum transmission” or color balance and rendition. The lens surfaces are carefully cleaned before coating. Techniques for applying coatings and the coatings themselves are major selling points for a manufacturer’s lenses and are carefully guarded secrets.

Some types of coatings include metal oxides, light-alloy fluorides, and layers of quartz that are applied to lenses and mirrors by a vacuum process. Several layers of coating may be applied for the best color and light transmission, but excessive coating can reduce the light that passes through the lens and limit its usefulness.

- The front and rear lens groups in 50mm f1.4 are symmetrical in optical design. Symmetrical lens construction is a feature of standard lenses which is not found in wide-angle or telephoto lenses. Main advantage of this optical design is permitting a large maximum aperture and still maintain excellent color reproduction. Because of these qualities, standard lenses are usually regarded as a starting point from which to build a lens.

- “ED” (extra-low dispersion), “LD” (low dispersion), “SLD” (special low dispersion), “ELD” (extraordinary low dispersion), and “ULD” (ultra-low dispersion),

- “aspheric.” Aspherical (ASPH) surfaces are lens surfaces that, unlike spherical concave and convex surfaces common to most lens elements, have counter-curves toward their edges that help maintain higher levels of sharpness toward the edges of the frame, which is particularly beneficial in the case of wide-angle lenses.

- Most commonly used in the design of telephoto lenses, LD, ED, ELD, ULD and SLD glass elements are usually in groups called “achromatic doublets,” in which a positive element made of low-dispersion glass is bonded to a complementary negative element of higher-dispersion glass, creating a single, higher-performance element group that greatly narrows the distance between each of the image’s color layers as they strike the surface of the imaging sensor.

Advantages Cinema Lenses over Photographic lens

- Totally reliable markings

- Uniform filter threads and front diameters

- Focus throw- long

- Aperture Ring

- Extremely smooth zoom movement

- Focus gears/teeth

- Designed to focus using…follow focus system

CJ Rajkumar

Author/Cinematographer.