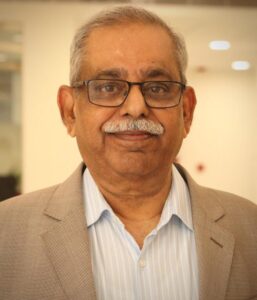

LAD system : S.SIVARAMAN!

Feb 15 2024

It’s true that while digital filmmaking dominates much of the industry, celluloid still reigns supreme in high-budget Hollywood projects, particularly in formats like the original IMAX, which exclusively uses film stock. Prasad film Laboratories in Chennai has left an undeniable mark on film post-production, especially in the realm of processing and printing. National Award-winning cinematographer PC Sreeram has even lauded their ability to deliver consistent image quality in release prints.

Speaking with S.Sivaraman, a legendary technician and former Operations Manager at Prasad Color Lab, we’ll delve into the technology behind achieving consistent image quality in release prints.

LAD System

Is a QC procedure introduced by KODAK Company , the undisputed leaders in imaging technology to help the lab to produce consistent results in production of release prints, otherwise called bulk prints. Once the DP is fully satisfied with the colour balance of the final answer print in terms of RGB values and colour balance of individual shots / scenes as well as the over all brightness and colour saturation, the laboratory takes his approval in writing and goes ahead with the striking of release prints.

However to produce consistent results in each print over a period is always a challenge for the Lab. Even if the lab has a perfectly controlled process in terms of chemistry and mechanical parameters , every time a new batch of emulsion( raw stock) is used they have to test it and set a new Trim Setting in the printing machine.

( Trim setting is used to filter out the unwanted colour bias introduced by the new batch and match the over all colour balance of the new print to the approved answer print. It is easier said than done. The consistency depends on the subjective judgement of the lab supervisor/ colour grader. This gives room for variations.

Demystifying the LAD System: Consistent Color for Motion Picture Prints

The quest for consistent color in motion picture prints has been a constant challenge for laboratories. Even with meticulous control over chemistry and machinery, variations can occur due to differing film batches and subjective judgment during the printing process. Enter the *Laboratory Aim Density (LAD) system*, a groundbreaking innovation by Kodak that takes the guesswork out of color balancing, ensuring uniformity across prints.

*The Challenge: Maintaining Color Consistency*

Before LAD, achieving consistent color involved subjective interpretation by lab supervisors. They used “trim settings” on printing machines to adjust for color biases introduced by new film batches, relying heavily on their judgment to match the approved “answer print.” This inherent subjectivity inevitably led to variations, especially when working across different laboratories or film batches.

*LAD System: A Shift towards Objectivity*

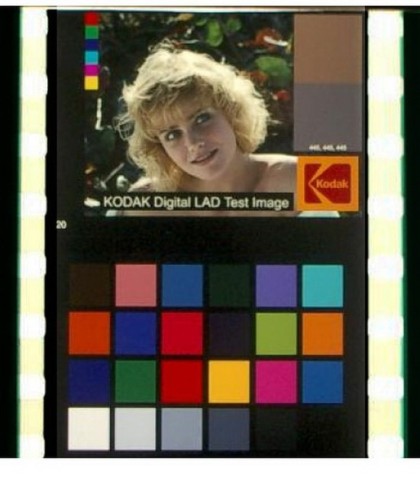

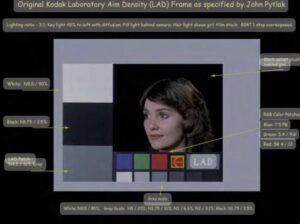

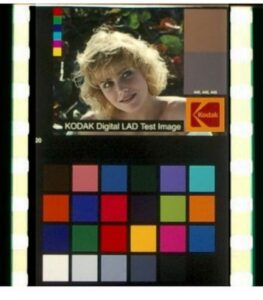

LAD takes a quantitative approach, replacing subjective judgment with precise measurements. The system utilizes a simple yet powerful tool: a *LAD patch*, spliced into the leader of the negative or duplicate negative. This patch features a color negative of an 18% reflectance grey card, representing the average scene density and human skin tone. Additionally, a color chart might be included for further reference.

*The Process:*

1. LAD patch inclusion: The LAD patch is spliced into the negative leader.

2. Print creation: Release prints are created using the negative with the LAD patch.

3. Density measurements: The printed LAD patch’s RGB values are precisely measured using densitometry.

4. Trim setting adjustments: Based on the measured values, the lab adjusts the printing machine’s “trim settings” to match the LAD patch’s density to the manufacturer’s *AIM densities*.

5. Iteration and perfection: This process is repeated until the print’s RGB densities perfectly match the AIM densities, ensuring consistent color balance.

*Benefits of the LAD System:*

Objectivity: Eliminates subjective judgment, leading to more consistent color across prints.

Global Consistency:* Enables consistent prints across different labs and film batches, as long as they participate in Kodak’s inter-laboratory survey system or are Image Care certified.

* *Streamlined Workflow:* Simplified workflow with readily available LAD patches, reducing time and effort.

Impact on Motion Picture Processing and Printing:

LAD has revolutionized the motion picture industry by ensuring consistent color across prints, regardless of location, lab, or film batch. This has:

*Enhanced viewer experience:* Consistent color ensures viewers enjoy the film’s intended visuals across different theaters and screenings.

*Improved communication and collaboration:* Collaboration among filmmakers, labs, and distributors is easier with standardized color representation.

*Reduced costs and time:* LAD’s efficiency reduces the need for multiple print corrections, saving time and resources.

Conclusion:

The LAD system is a testament to Kodak’s dedication to innovation and quality in motion picture processing and printing. By replacing subjectivity with objective measurements, LAD has empowered labs to achieve consistent color, elevating the viewing experience for audiences worldwide.

The major advantage of this procedure is that you can ship out the final Dupe Negative or original negatives to any lab across geographies to stike release prints which are exactly the same standard. Provided those labs are participants in the inter laboratory survey system of Kodak or an Image Care certified lab.

Prasad film Laboratories in chennai was under Kodak Image Care certified program

Conversation by : S.Sivaraman

Drafted by : C.J.Rajkumar