SICA event : Flexbot 2.0 Cinetica!

Mar 24 2025

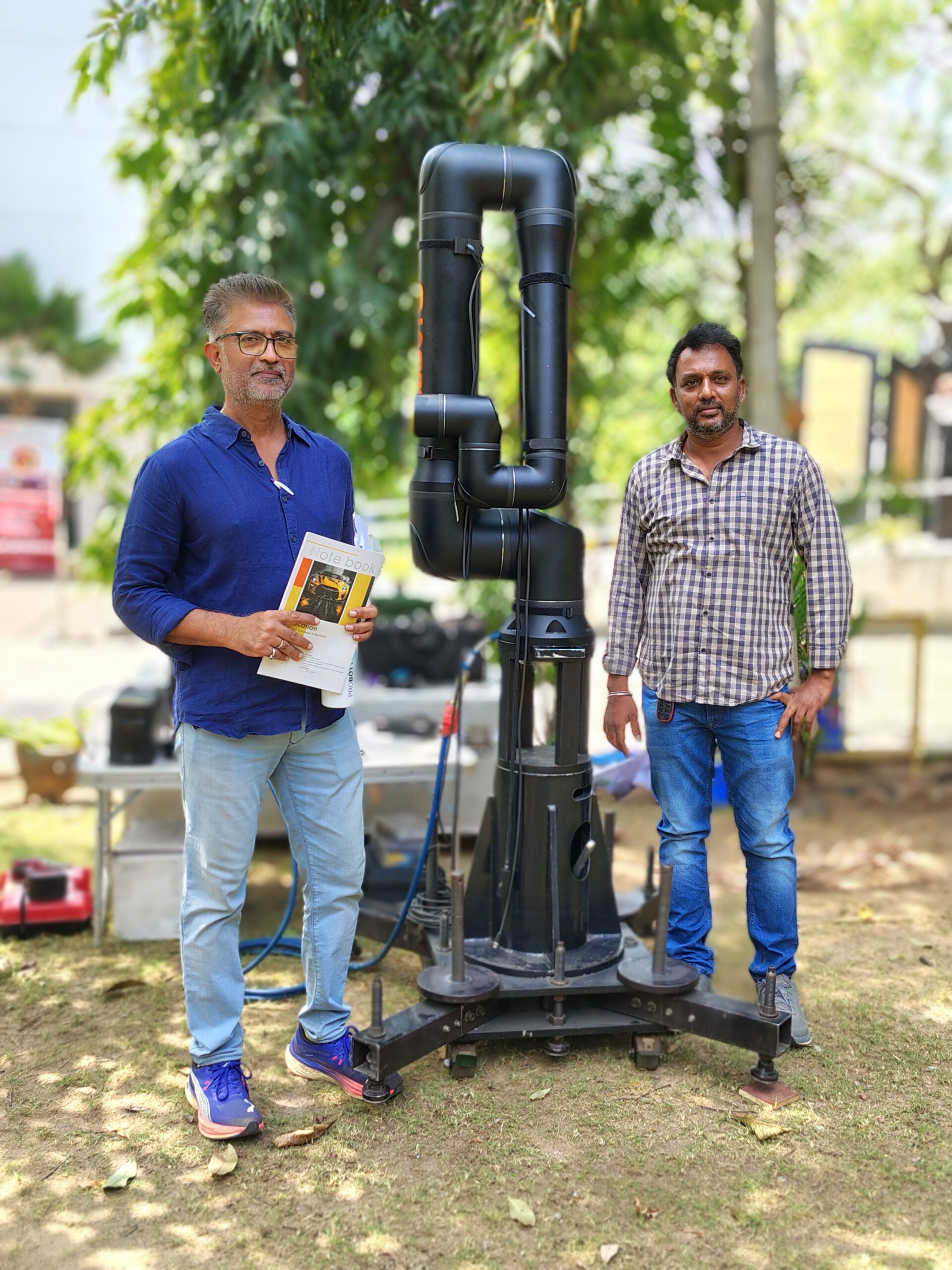

SICA with CAM BENEFIT Trust program of bringing educational and spreading technical awareness extended its activities of organising an interesting program on 23-3-25 at Prasad lab theatre premises as post-lunch event at the Open Gardens was a grand success, featuring three major camera grip systems. The Flexport 2.0 robotic motion control solution, Nu.tron, which provides an immersive hands-on movement experience, and Flowcine, a three-axis system, were showcased. Cinematographers had the opportunity for hands-on experimentation, exploring camera movements, robotic arm capabilities, and the ease of setup for these advanced devices.

This system is been spearheaded by Mr.Nageshwar Rao Gude Cinetica gimbal house at Hyderabad.

They have collaborated with many DOPs to name few SICA members Rathnavelu, Manoj Paramahamsa, Nirav Shah, Ravi Varman, Tirru and Madhee.

FLEXBOT 2.0 is a cutting-edge robotic motion control system.

The Flexbot 2.0 is a portable robotic motion control system designed for precise, programmable, and repeatable camera movements with minimal setup. It features rapid on-set programming via keyframe positioning, using hand-guiding or operator controls. The SLIM path planning tools help design smooth motion paths.

Key Specifications:

1.9m reach with speeds up to 9ft/sec

Supports heavy camera payloads up to 20kg

Integrated lens control with 3-axis & 6-axis position control (Roll, XYZ, Pantel)

Synchronized outputs available

Robotic arm weighs 65kg

No PC or laptop required for operation

Runs on single-phase power

Ideal for film and commercial production, Flexbot 2.0 provides advanced motion control in a compact and efficient system.

Typically, robotic motion control systems like FLEXBOT 2.0 use a combination of hardware and software components to control and synchronize movement. These components may include:

1. Motors and actuators: These are the physical components that move and control the robot’s joints or axes.

2. Control systems: These are the electronic systems that control the motors and actuators, using algorithms and software to determine the desired movement.

3. Sensors and feedback systems: These are used to monitor the robot’s movement and provide feedback to the control system, ensuring accurate and precise movement.

The FLEXBOT 2.0 likely uses advanced technologies such as artificial intelligence, machine learning, or computer vision to enable precise and flexible movement control.

The modular design of the Cinetica Nutron FLEXBOT 2.0 is a key feature that allows for high customizability and flexibility. Here’s a breakdown of what it entails:

Modular Components

1. Motion Control Modules: These modules contain the core motion control technology, including motors, drives, and control algorithms.

2. Interface Modules: These modules provide connectivity options, such as Ethernet, USB, or wireless communication protocols.

3. Sensor Modules: These modules integrate various sensors, like encoders, cameras, or force sensors, to provide real-time feedback and enable precise motion control.

4. Actuator Modules: These modules contain the mechanical components that execute the motion, such as robotic arms, grippers, or linear stages.

Modular Architecture

The FLEXBOT 2.0’s modular design allows users to:

1. Mix-and-Match Modules: Combine different modules to create a customized system tailored to specific application requirements.

2. Add or Remove Modules: Easily add or remove modules as needed, allowing for seamless upgrades or reconfigurations.

3. Reconfigure Module Connections Rearrange module connections to adapt to changing application needs or to optimize system performance.

Benefits of Modular Design

The modular design of the FLEXBOT 2.0 offers several benefits:

1. Increased Flexibility Easily adapt the system to new applications or tasks.

2. Reduced Development Time: Quickly assemble and test a customized system using pre-existing modules.

3. Improved Scalability: Easily add or remove modules as needed to scale the system up or down.

4. Enhanced Maintainability: Simplify maintenance and repair by replacing individual modules rather than the entire system.

By providing a modular design, FLEXBOT 2.0 enables users to create a customized motion control system that meets their specific needs, while also allowing for future upgrades and adaptations.

The Flowcine BlackArm is a professional-grade stabilization system designed for mounting gimbals on moving vehicles. It provides superior dampening and stabilization for dynamic cinematography. Here are its key advantages:

1. Advanced 3-Axis Dampening

The system absorbs and reduces vibrations across roll, tilt, and vertical motion, making it ideal for capturing smooth footage in rough conditions.

2. Additional Vibration Mount

Further stabilizes footage by mitigating high-frequency vibrations from vehicle movement, ensuring cinematic quality even on rough terrain.

3. Hard-Mount System for Vehicles

Securely attaches gimbals to cars, ATVs, boats, snowmobiles, and other moving platforms, expanding shooting possibilities for action sequences.

4. Reduced Shaky Footage

Helps eliminate unwanted micro-jitters and shakes, which are common in handheld or basic rig setups, resulting in a fluid and professional look.

5. Compatibility with High-End Gimbals

Works seamlessly with gimbals like DJI Ronin 2, Freefly MoVI Pro, and other professional stabilizers, allowing flexible use with various camera systems.

6. Customizable Spring and Dampening System

Adjustable spring tension to accommodate different camera weights, making it versatile for both lightweight and heavy camera setups.

7. Ideal for High-Speed Filmmaking

Perfect for car chases, off-road sequences, and water-based cinematography, ensuring smooth footage even at high speeds.

8. Durable Build for Harsh Environments

Made from high-quality materials, ensuring long-term reliability in demanding shooting conditions, from deserts to snowy landscapes.

The Cineatica Nu.tron offers several advantages for professional filmmakers and cinematographers:

1. Exceptional Freedom of Movement

Allows precise, weightless control over the camera.

Enables smooth, natural perspective changes.

Enhances creative framing with dynamic shots.

2. Stability & Smooth Operation

Provides stability while maintaining flexibility.

Reduces vibrations and unwanted movements.

Ensures high-quality, fluid cinematography.

3. High Payload Capacity

Supports cameras up to 20 kg, accommodating professional cinema rigs.

Counterweight system allows up to 50 kg, ensuring perfect balance.

4. Extended Range

5-meter horizontal range and 3.6-meter vertical range allow for versatile shooting angles.

Ideal for complex tracking shots, overheads, and low-angle movements.

5. Universal Compatibility

Euromount and Mitchell interface ensure compatibility with various industry-standard equipment.

Flat base tripod connection fits professional tripods with 300 kg load capacity.

6. Versatile Applications

Suitable for feature films, commercials, sports broadcasting, and live events.

Works well for both handheld-style and stabilized motion shots.

7. Lightweight & Portable

Net weight of 33.5 kg, making it manageable for transport and setup.

Compact design compared to traditional camera rigs with similar capabilities.

Finally SICA members and student community had elaborate interaction with operative technicians about assembling, transportation advantages of these equipments and creative liberties of camera moves.

Article by

CJ Rajkumar

Author/ Cinematigrapher